Since last summer, I have been working at a mechanical engineering lab at UC Berkeley conducting research into new types of 3D printing composites. While I can’t provide too many details, I will attempt to describe the theoretical foundations for my work.

The 3D printers I work with are known as Fused deposition modeling (FDM) printers. They are the 3D printers you are most likely familiar with.

First, a few diagrams detailing how they actually work:

There are many applications and advantages to these printers. For instance, consumers or businesses can quickly and easily CAD and 3D print new parts (techniques known as rapid prototyping). There are therefore a variety of different industrial applications for these printers.

However, one of the main drawbacks for these is the lack of variety of different polymer feedstocks to print with. The main polymers used here are acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA), but these are often unsuitable for many applications. For instance, a durable, strong, and inert polymer would be wonderful for orthopedic implants in the medical industry, as printers could be used to customize it for individual patients.

Unfortunately, two important industrial polymers are unsuitable for printing because of one key property: thermal expansion. When a material is heated, it expands according to a specific ratio that varies by material.

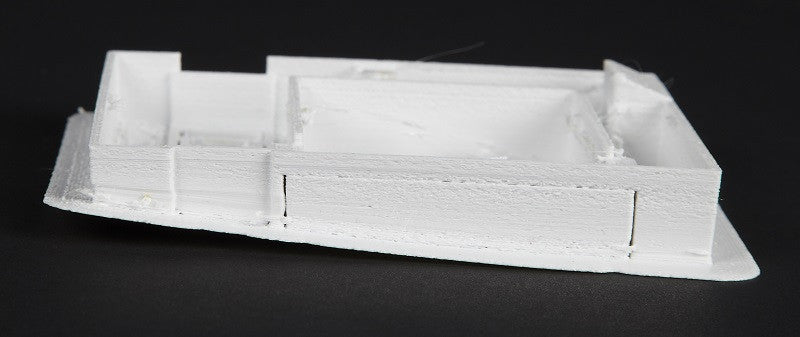

As the polymer is laid down, a thermal gradient appears; the bottom is the coldest, and therefore contracts, while the top is hot, and doesn’t contract. This gradient not only leads to anisotropic thermal expansion (causing residual stresses in the material), but also causes warping, as the print gets twisted and ultimately fails.

To remedy this, the platform on which the filament is deposited is often heated, as it reduces the severity of the thermal gradient, reducing warping. However, while this works with some polymers (ABS has a high thermal expansion, but a build plate fixes it), many still warp too much for a heated build plate to be of use.

Thus, a way to reduce the thermal expansion of these polymers is highly desirable, as it would mean they are now viable for use in industrial applications.

To do this, I add carbon fiber to the polymers. Carbon fiber has a negative thermal expansion, which means that it actually slightly contracts upon being heated. By creating what’s known as a carbon fiber reinforced polymer (CFRP), I am able to reduce the expansion of the polymer to be near zero, drastically improving printability. The print has the dual benefit of being stronger, more brittle, more wear resistant, and generally superior mechanically speaking.

Finally, I model the CFRP’s thermal and mechanical values using a program I wrote (discussed here), and compare them to the actual, experimental values.