Theory of Operation

This device relies primarily on the Joule-Thomson effect, which is the effect that describes the temperature change of a real gas as it expands through a throttling valve.

If an ideal gas at pressure P1 flows through a butterfly valve into a lower-pressure region of P2, then there is no temperature change because the process is isenthalpic.

This video demonstrates:

However, this is only true for an ideal gas. Real gases, on the other hand, have intermolecular forces, volume, and undergo inelastic collisions (kinetic energy is not conserved). This means that, in fact, a real gas may change temperature when undergoing throttling.

This is governed by the Joule-Thomson Coefficient, defined as:

μ= ∂T/∂P

[The Joule-Thomson Coefficient is defined as the change in temperature for an infinitesimal change in pressure, with all else constant.]

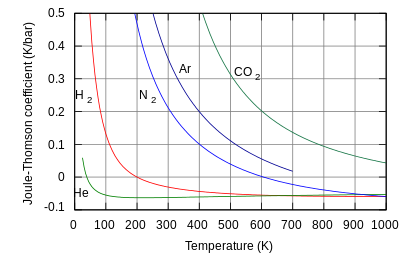

μ changes for a given gas at a given temperature. This graph shows a few:

When the coefficient for a gas is negative, it gains heat when undergoing throttling; when it’s positive, it loses heat. This is because throttling decreases the pressure, and a positive J-T coefficient means that T decreases as well.

The temperature at which the J-T coefficient is 0 is known as the inversion temperature (Ti), and below that, a gas will lose heat to throttling. This presents a problem for me: the inversion temperature for helium is 45K, which cannot be reached easily. I therefore have to use a different gas in order to cool down helium. I plan to use neon, with a Ti of -3C and a liquefaction temperature of 27K to cool the device enough such that Helium can be used.

In addition, by creating a large pressure gradient, a gas will cool down more. Thus, a 3000 PSI air compressor will be used, creating a very steep drop in pressure and therefore temperature.

Essentially, what I am creating can be best described as a Hampson-Linde helium liquefier, as I plan to have the gas run through many cycles. Here is a diagram of one:

This is more or less the same type of machine I am making, just scaled up. One problem is that since helium liquefies at 4K, everything needs to be insulated and cryogenic rated. Another issue is the extreme pressure. At 3000 PSI, even stainless steel tubing can burst. I’m using a safety factor of 12 to account for this and the fact that the temperature will be lower.

Another problem is with the compressor itself. The machine is actually WWII surplus (see pic) and requires very weird power input levels at 3 Phase, 200V, 400 Hz AC power.

This requires me to have to use a transformer connected to a variable frequency drive connected to the power input line. Not fun at all.

At the moment, I’m creating entire gas handling system. After that, I’ll work on creating the reservoir and hooking it all together. I estimate completion by June.